Home

>> Products

>> OMRON

>> Temperature controller

>> Modularization

>> EJ1G-HFUB-NFLK Modular Temperature Controller for Gradient Temperature Control

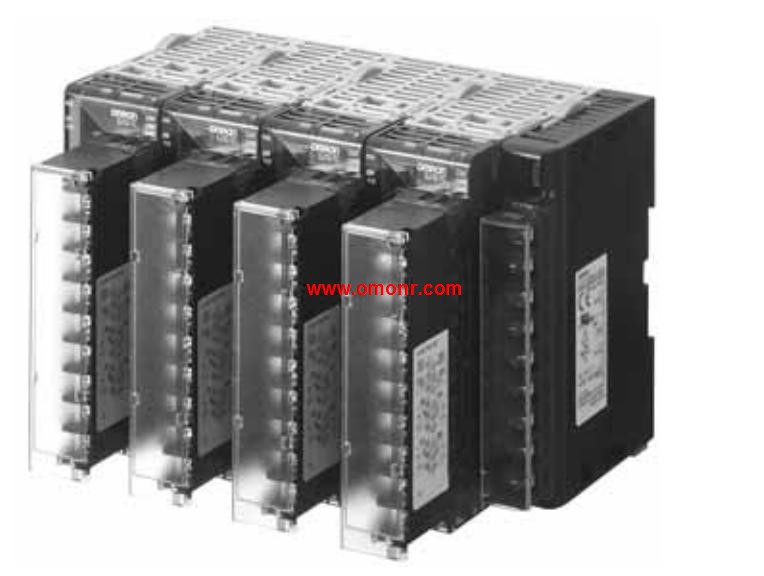

EJ1G-HFUB-NFLK Modular Temperature Controller for Gradient Temperature Control

OMRON EJ1G-HFUB-NFLK Manual And Instructions

EJ1G-HFUB-NFLK datasheetPDF datasheet

EJ1G-HFUB-NFLK OPERATION MANUAL

EJ1G-HFUB-NFLK User's Manual

EJ1G-HFUB-NFLK User's Manual

EJ1G-HFUB-NFLK INSTRUCTION sheet

OMRON EJ1G-HFUB-NFLK Product information and technical parameters:

Brand: OMRON

Name: Modular Temperature Controller for Gradient Temperature Control

Model: EJ1G-HFUB-NFLK

Name: HFU (gradient temperature control) (See note 1.).

Power supply voltage: 24 VDC supplied from the End Unit.

No. of control points: None.

Control outputs 1 and 2: None.

Control outputs 3 and 4: None.

Auxiliary output: Transistor output: 4 points (sourcing).

Functions: Heater burnout alarm, None; Event inputs, 4.

Communications functions: From End Unit, Port A, RS-485; Port C, RS-485;

or RS-232C, selectable.

Input type: No input.

Terminal: Screw-less clamp.

Gradient Temperature Control to Achieve.

Consistent Layer Temperature.

Perform gradient temperature control ranging from 2 to 32 channels.

Perform 2-channel gradient temperature control for up to 16,

groups, or 32-channel gradient temperature control for up to 2 groups.

Set gradient temperature control or 2-PID control for each group.

Reduce design work for ladder programming with programless,

connections to Programmable Controllers. (The same feature,

as Standard-control EJ1 Models.).

Connect directly to the G3ZA Multi-channel Power Controller,

using optimum cycle control for high-accuracy control with minimal noise.

...More relevant models >>>>

EJ1G-HFUB-NFLK datasheetPDF datasheet

EJ1G-HFUB-NFLK OPERATION MANUAL

EJ1G-HFUB-NFLK User's Manual

EJ1G-HFUB-NFLK User's Manual

EJ1G-HFUB-NFLK INSTRUCTION sheet

OMRON EJ1G-HFUB-NFLK Product information and technical parameters:

Brand: OMRON

Name: Modular Temperature Controller for Gradient Temperature Control

Model: EJ1G-HFUB-NFLK

Name: HFU (gradient temperature control) (See note 1.).

Power supply voltage: 24 VDC supplied from the End Unit.

No. of control points: None.

Control outputs 1 and 2: None.

Control outputs 3 and 4: None.

Auxiliary output: Transistor output: 4 points (sourcing).

Functions: Heater burnout alarm, None; Event inputs, 4.

Communications functions: From End Unit, Port A, RS-485; Port C, RS-485;

or RS-232C, selectable.

Input type: No input.

Terminal: Screw-less clamp.

Gradient Temperature Control to Achieve.

Consistent Layer Temperature.

Perform gradient temperature control ranging from 2 to 32 channels.

Perform 2-channel gradient temperature control for up to 16,

groups, or 32-channel gradient temperature control for up to 2 groups.

Set gradient temperature control or 2-PID control for each group.

Reduce design work for ladder programming with programless,

connections to Programmable Controllers. (The same feature,

as Standard-control EJ1 Models.).

Connect directly to the G3ZA Multi-channel Power Controller,

using optimum cycle control for high-accuracy control with minimal noise.

Size: 48 x 48mm.

Control output 1: voltage output (SSR driver).

Control output 2:--.

Auxiliary output: 2 independent points.

Power supply voltage: AC100 ~ 240V.

Terminal type: screw terminal table type.

Input category: full range multi input.

Heater break, SSR fault detection function: -.

Communication: - EJ1G-HFUB-NFLK.

Event input: 2 points.

Remote SP input: -.

Transfer output: have.

Using large font PV display (white), improve visibility EJ1G-HFUB-NFLK

Selection, operation and setting.

Functional performance of input and output points.

Support for more extensive range of applications.

Using high PV 15.2mm display (white), improve visibility.

High speed sampling to achieve 50ms.

With auxiliary output (maximum 3 points), event input (maximum 4 points), the transmission output,

Remote SP input function, support for a variety of applications EJ1G-HFUB-NFLK.

E5CC 60mm has a depth of slender body.

The use of communication adapter cable (sold separately) connected with a computer.

After that, no power supply connection can be set.

It can be easily set by CX-Thermo (sold separately).

Easy to connect with PLC through no program communication EJ1G-HFUB-NFLK.

Combined temperature control device through component communication. Size: 96 x 96mm.

Ontology: terminal type, temperature input type.

Category: control output 1 point type (power supply AC100 ~ 240V).

Shell color: black.

Control output: relay output.

Control mode: standard or heating cooling.

Auxiliary output points: 3 points.

Heater with broken wire, SSR fault, heater over current detection function /ES1B power supply: single phase heater with detection function.

Event input points: -.

Transfer output: -.

Communication: RS-232C.

The general temperature controller 96mm, 48 * 96mm square has been upgraded to improve the performance and function of /.

Indicates that the accuracy of the upgrade, increase the function of prevention and maintenance, further enhance the performance.

Add PV/SV state display function, to see the state of the thermostat

(automatiic / manual, RUN/STOP, alarm), interactive display PV/SV EJ1G-HFUB-NFLK.

Increase the number of control output ON/OFF counting function, can prevent the maintenance of temperature controller internal relay.

Increased the 3 segment display, which cann display the current value / target / operation EJ1G-HFUB-NFLK.

Increased the PF key, the distribution of automatic / manual, RUN/STOP, etc., can be a key operation.

Control output 1: voltage output (SSR driver).

Control output 2:--.

Auxiliary output: 2 independent points.

Power supply voltage: AC100 ~ 240V.

Terminal type: screw terminal table type.

Input category: full range multi input.

Heater break, SSR fault detection function: -.

Communication: - EJ1G-HFUB-NFLK.

Event input: 2 points.

Remote SP input: -.

Transfer output: have.

Using large font PV display (white), improve visibility EJ1G-HFUB-NFLK

Selection, operation and setting.

Functional performance of input and output points.

Support for more extensive range of applications.

Using high PV 15.2mm display (white), improve visibility.

High speed sampling to achieve 50ms.

With auxiliary output (maximum 3 points), event input (maximum 4 points), the transmission output,

Remote SP input function, support for a variety of applications EJ1G-HFUB-NFLK.

E5CC 60mm has a depth of slender body.

The use of communication adapter cable (sold separately) connected with a computer.

After that, no power supply connection can be set.

It can be easily set by CX-Thermo (sold separately).

Easy to connect with PLC through no program communication EJ1G-HFUB-NFLK.

Combined temperature control device through component communication. Size: 96 x 96mm.

Ontology: terminal type, temperature input type.

Category: control output 1 point type (power supply AC100 ~ 240V).

Shell color: black.

Control output: relay output.

Control mode: standard or heating cooling.

Auxiliary output points: 3 points.

Heater with broken wire, SSR fault, heater over current detection function /ES1B power supply: single phase heater with detection function.

Event input points: -.

Transfer output: -.

Communication: RS-232C.

The general temperature controller 96mm, 48 * 96mm square has been upgraded to improve the performance and function of /.

Indicates that the accuracy of the upgrade, increase the function of prevention and maintenance, further enhance the performance.

Add PV/SV state display function, to see the state of the thermostat

(automatiic / manual, RUN/STOP, alarm), interactive display PV/SV EJ1G-HFUB-NFLK.

Increase the number of control output ON/OFF counting function, can prevent the maintenance of temperature controller internal relay.

Increased the 3 segment display, which cann display the current value / target / operation EJ1G-HFUB-NFLK.

Increased the PF key, the distribution of automatic / manual, RUN/STOP, etc., can be a key operation.

...More relevant models >>>>

Last one: OMRON Modular Temperature Controller for Gradient Temperature Control EJ1G-HFUA-NFLK

Last one: OMRON Modular Temperature Controller for Gradient Temperature Control EJ1G-HFUA-NFLK next one: OMRON Modular Temperature Controller for Gradient Temperature Control EJ1G-HFUA-NFL2

next one: OMRON Modular Temperature Controller for Gradient Temperature Control EJ1G-HFUA-NFL2

Related download